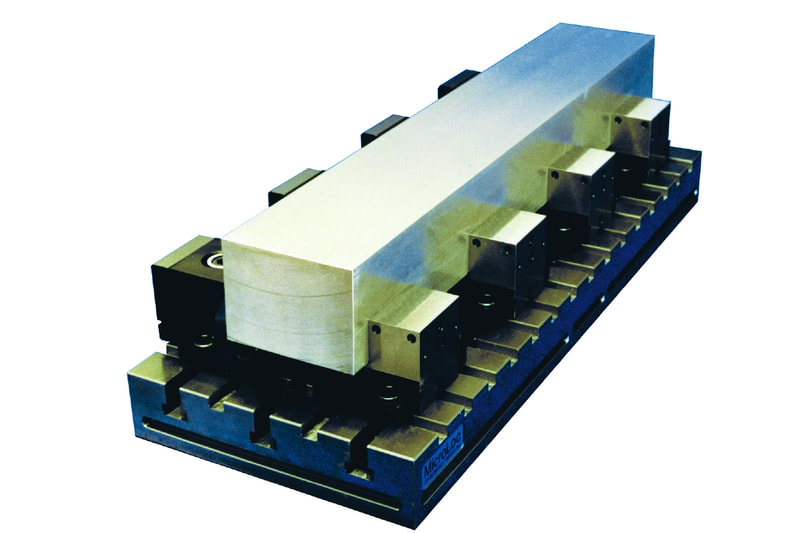

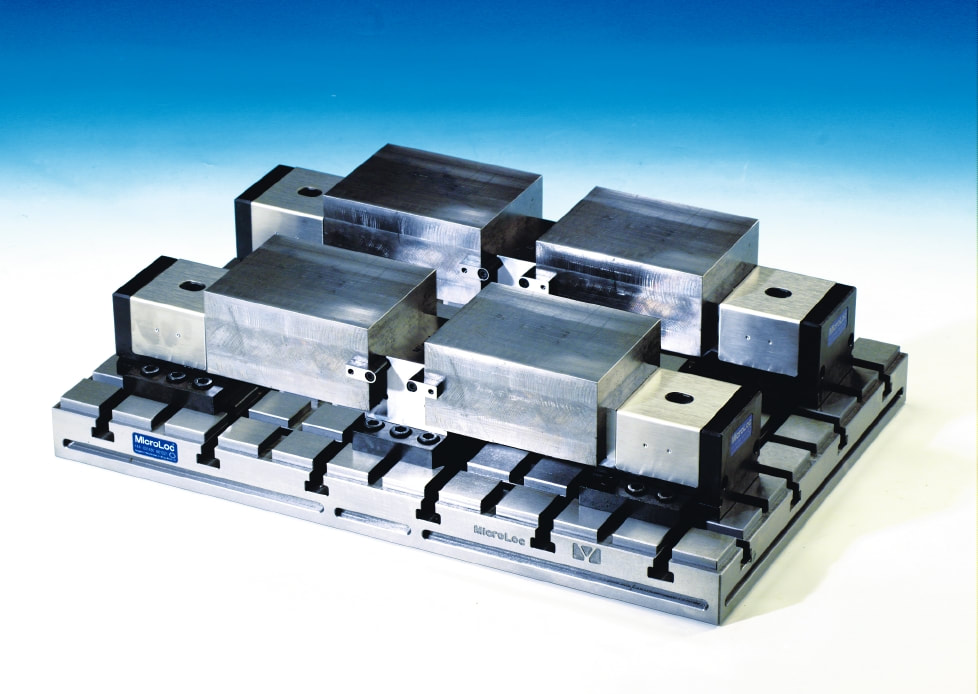

Versatile and High Density Workholding

Why MicroLoc?

|

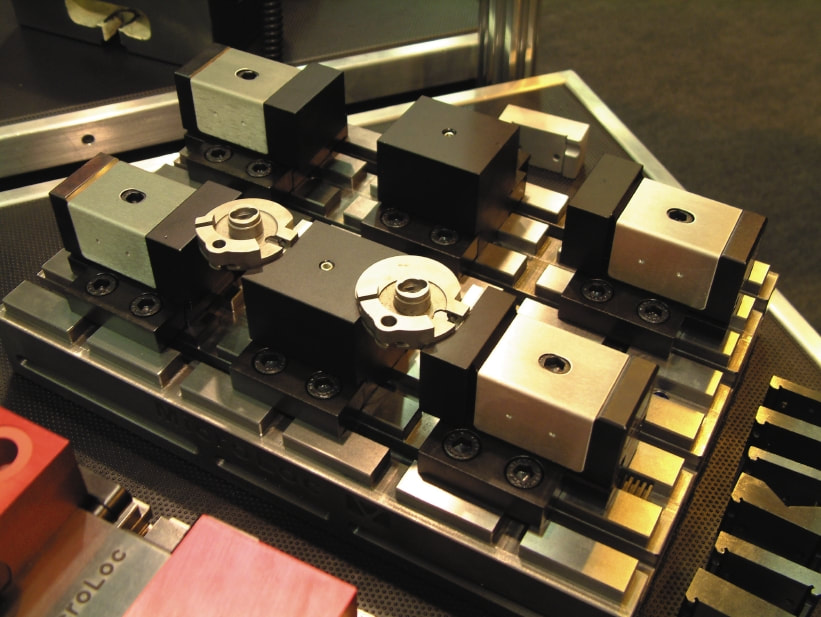

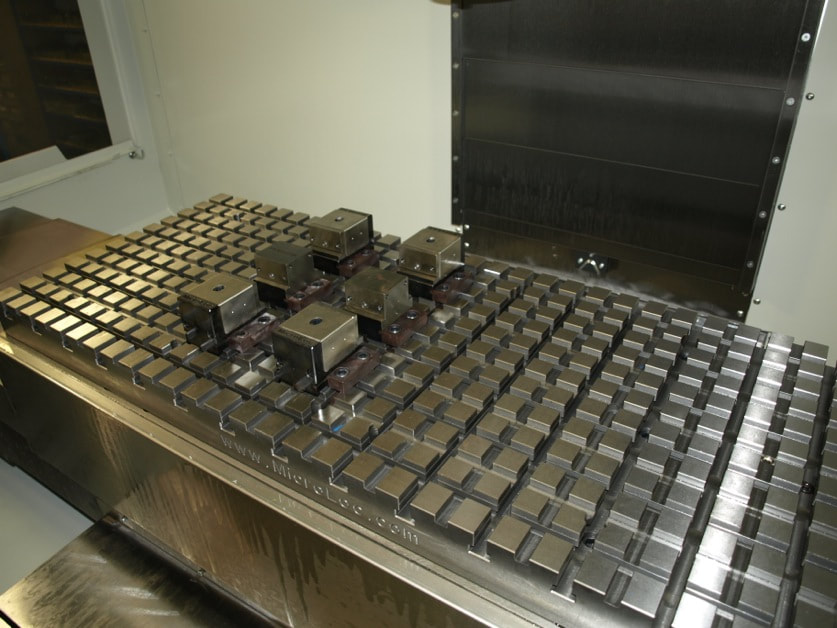

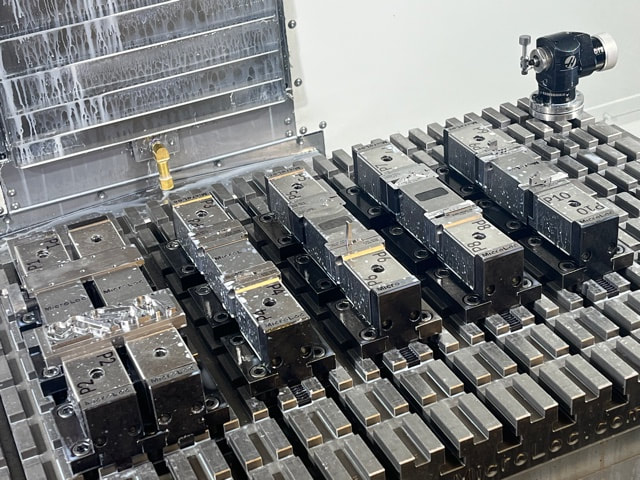

Our machine tool customers are continually looking for efficiency gains and many are now exploring automation. However, in many cases, they are missing the low hanging fruit right in front of their eyes. Traditional vice workholding still has a market leading share in the CNC space, but customers often miss the efficiency they can gain by investing in a modern workholding system designed for the machine shop of today. Quality and high density workholding can act as a form of automation in its own right when coupled with CNC machinery. A CNC with traditional vices bolted onto the table may run unmanned for an hour on a certain parts. Triple or Quadruple the number of parts may fit onto a high density MicroLoc system, increasing the unmanned run time on that same machine to 3 or 4 hours. Production increases, workload decreases and all the flexibility of a vice system remains. Interested in learning how MicroLoc can improve your business? Request a visit and our team will give an in person demonstration of the system. |

12 parts instead of 4 parts

|

|

|