|

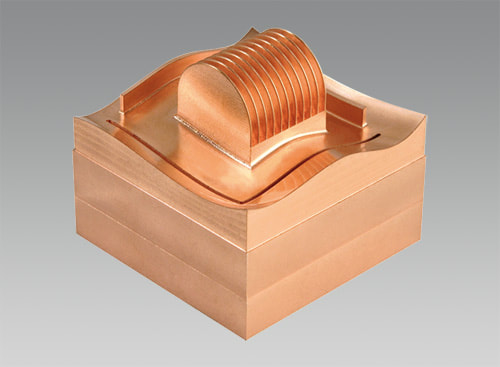

Roeders specialise in high speed machining in applications where accuracy and surface finish demands are at their most extreme.

Widely regarded as among the most accurate machine tools on the market, Roeders have built up a stellar reputation in the ultra high precision category. Typical Applications Include: Mould and Die Production High Precision Production Parts Minting Technology Optical Componets Impellor, Blisks and Turbine Blades Medical Components |

Visit Röders Germany for detailed product and company information.

|

Technical Capabilites

This is a small sample of some of the technologies available with Roeders

|

|

|

Learn how Galway Tool and Mould reduced complex mould cycle times from 40 hours down to 8 hours while implentating a lights out machining process |

|

|

Hear what Crossen Engineering have to say about their 3 axis Roeders machine. So accurate you can use it as a CMM |

|

|

Listen to Damien Dowd from Galway Tool and Mould discuss how a zero failure rates is demanded and achieved on their medical device moulds using their fleet of Roeders high speed machining centres |

|

|

James Lawrence from Lawrence Engineering holds a discussion on how adding Roeders has transformed their lead times on moulds. Previously the process involved pre milling, sending out for hardening, then performing EDM and finally labourious hand polishing With their Roeders they are capable of hard milling to extreme accuracies meaning parts can be produced in one hit and all the other stages (Pre milling, hardening, EDM, polishing) have been eliminated. What previously took 4 -6 weeks is now turned around to the customer in 1 - 2 weeks. |